Ki-Max Lighting is a leading hospitality lighting manufacturer, serving and producing an extensive clientele that includes Hotel designers, Furniture companies, Lighting companies, Interior designers, Architects, Contractors, and FF&E procurement specialists. With over a decade of experience in custom lighting production, we understand the critical importance of precision and attention to detail in bringing a designer’s vision to life. Even the slightest difference between a conceptual design and the final product can significantly impact the success of a hotel project.

Spanning over 3000 square meters, our production facility has a monthly capacity of 50,000 units. Our products are exported to countries worldwide, with a strong presence in the Middle East, Europe, North Africa, North America, and Australia. Our range includes chandeliers, table lamps, floor lamps, wall sconces, smart mirror lights, ceiling fans with Lights, bathroom wall lamps, and hotel custom lighting. We work with materials such as stainless steel, copper, rattan, wood, metal, acrylic, resin, fabric, marble, glass, ceramic, and bamboo, utilizing different processes and techniques to tailor-made products that align with your visual concept.

Our adept team excels at custom lighting solutions to suit specific requirements and spaces, considering project themes, design aesthetics, project budget, product safety, stability, installation logistics, and transportation, among other crucial factors. We are dedicated to ensuring that our lighting designs not only enhance but harmonize with the overall vision of a project. In addition to our product offerings, we provide comprehensive lighting design services, collaborating closely with designers and architects to seamlessly integrate our solutions into their designs.

At Ki-Max Lighting, we enrich ambiance and elevate customer experiences through meticulously custom lighting solutions. Ours is keen to engage with you, understand your project’s needs, and demonstrate how our services and products can meet and exceed your expectations. We look forward to the opportunity to contribute to the success of your projects and establish a lasting partnership.

Production Process at Ki-Max Lighting

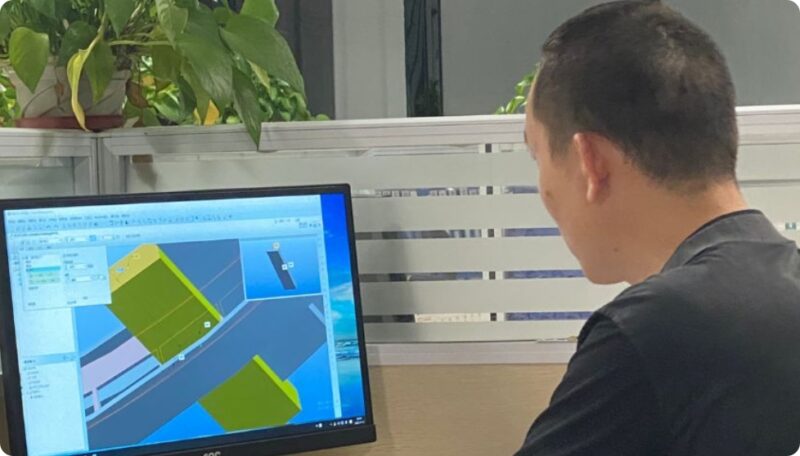

Lighting Design

After confirming the quotation for a specific lighting style, our team will discuss the details of your specific lighting product requirements with you, such as the installation method for chandeliers, ceiling load capacity, and the materials, dimensions, finishes, light sources, voltage, switch types, and dimming options to be used. Once all details are confirmed, our engineering team begins drafting shop drawings. For large fixtures or challenging lighting products, our engineers consider factors such as transportation, installation, ceiling load capacity, and safety to optimize the design, ensuring beauty, stability, safety, and durability from both the consumer’s and designer’s perspectives.

Materials and Finish Approval

While drafting shop drawings, the Ki-Max Lighting team produces finished samples of the manufacturing materials based on the client’s specific requirements. Materials include steel, brass, aluminum, stainless steel, resin, leather, fabric, silk, marble, plaster, acrylic, glass, wood, ceramic, crystal, bamboo, and rattan. Each material can have different finishes, with standard surface treatments including painting, powder coating, electroplating, vacuum plating, water printing, and patination. Designers can approve all our hotel lighting products’ finishes, ensuring durability and lasting quality.

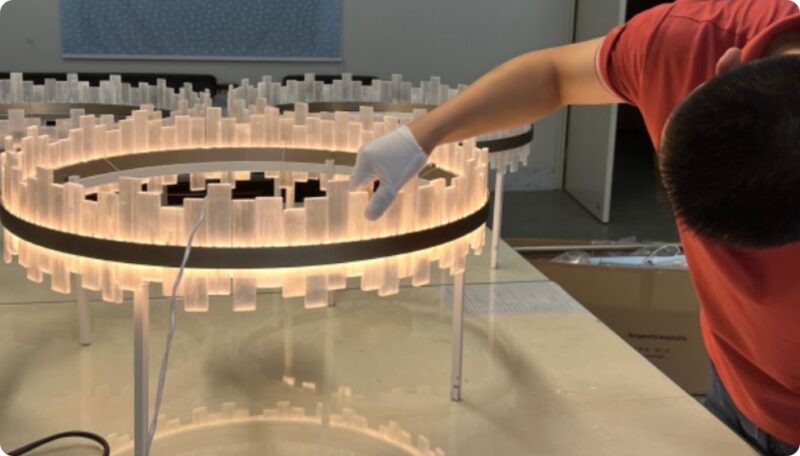

Production of Samples

After approving the drawings and all finishes, the Ki-Max Lighting team arranges the production of samples. Upon assembling and inspecting the structure and effect of the initial prototypes, our QC team checks and confirms the quality before proceeding with the finish treatment, ensuring high-quality product samples. The lead time for samples typically ranges from 30 to 40 days, and 50 to 60 days if tooling or molds are involved.

Mass Production

After approving samples and prototypes, the Ki-Max Lighting team schedules mass production. Our hardware processing workshop utilizes precision machining equipment for all metal materials. Hardware undergoes multiple processing steps such as welding, grinding, and polishing before moving on to finishing processes. Assembly starts once all components are collected, with an estimated production lead time of 30-45 days.

Quality Control

Our QC team, consisting of 5 members, conducts a full inspection of all materials upon arrival. After assembling the products, they perform a 100% inspection based on the drawings and approved finishes and take photographs to compile inspection reports to send to clients, or clients can arrange for their QC teams to inspect the factory.

Shipping

We currently offer Ex-Works pricing terms. After QC inspection approval, our team will update you with the packing list and invoice to schedule the shipping, or we will update you with the packing list and invoice about a week before the goods are ready. If you have not specified the freight forwarder, we can consult multiple freight companies to provide quotes for your selection.

Company & Team

Factory & Process

GET IN TOUCH

CONTACT US TO GET THE LATEST PRICE

No. 27, Fuqing 2nd Road, Henglan Town, Zhongshan City, Guangdong Province, China.

sales@ki-maxlighting.com

+86-+189 2663 9226